Chocolate may be one of the world’s oldest indulgences, but the technologies behind its production are rapidly evolving. From smart harvesting in cocoa farms to precision 3D printing and robotic handling on the production line, innovation is transforming every stage of chocolate making. At the centre of this transformation are the engineers designing the machinery – and increasingly, the software – that makes it all possible.

As the industry embraces automation, robotics, sustainability, and the principles of Industry 4.0, the chocolate production line is becoming more intelligent, efficient, and adaptable than ever. But with new capability comes a new challenge: how to protect the innovation that drives competitive advantage.

Smarter cocoa processing starts at the source

Innovation begins long before the chocolate ingredients reach a factory floor. In cocoa-growing regions, new technologies are helping address efficiency, quality, and environmental challenges.

For example, Mondelez has used drones and AI driven platforms to monitor crop health and facilitate fertilisation to improve cocoa crop yields.

Further innovations include:

- Robotic harvesters using vision systems to identify ripe pods and harvest efficiently;

- Automated shell-cracking machines to reduce post-harvest losses;

- AI-driven sorting systems that improve quality control and traceability.

These technologies lay the foundation for a more consistent and sustainable chocolate supply chain. But it’s in the factories where chocolate takes form that robotics and advanced machinery are truly redefining what is possible.

The rise of robotics in chocolate manufacturing

Robots are no longer a futuristic concept—they're already transforming chocolate production.

Whether it’s a high-throughput production line or a small-batch confectioner seeking consistent presentation, robotics improves speed, hygiene, and accuracy.

These robotic systems often involve a blend of mechanical engineering, AI-driven control systems, and sophisticated software interfaces—all of which may be eligible for intellectual property (IP) protection.

Precision tempering

Tempering is one of the most technically sensitive processes in chocolate making and traditionally relied upon skilled operators managing time, temperature, and motion to achieve a perfect crystalline structure for gloss and snap. Top UK confectionary machinery companies such as KeyChoc now offer fully automatic, continuous tempering machines,

Modern machines deliver precision tempering using:

- Real-time temperature sensors to monitor and adjust with extreme accuracy;

- Automated flow and shear control, tuned for different chocolate formulations;

- Pre-set profiles that adapt to origin, fat content, or desired finish;

- Feedback loops that adjust based on viscosity and crystal formation.

Precision tempering machines are not only improving quality and consistency – they’re also enabling faster product changeovers, reduced waste, and a more energy-efficient process. As manufacturers push for ever more reliable performance, innovations in heat exchange systems, rotor geometry, and adaptive control logic offer clear paths towards those goals.

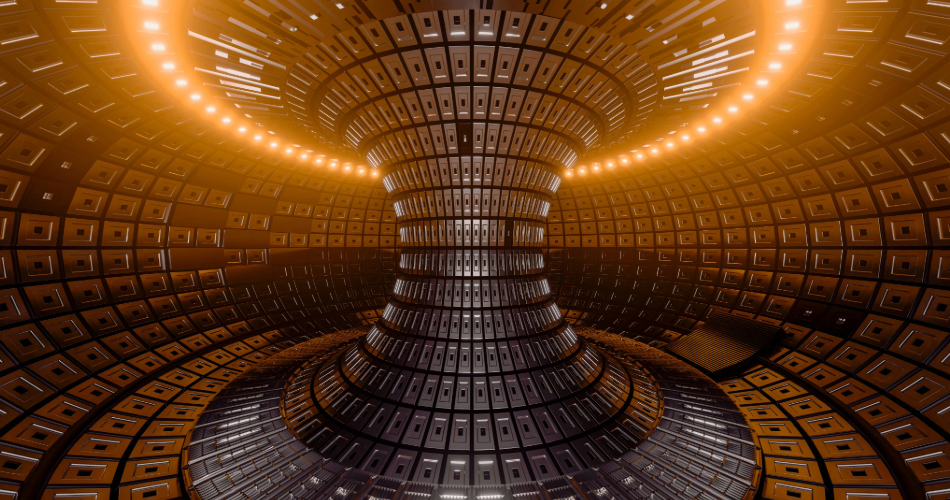

Chocolate production meets industry 4.0

The rise of robotics and intelligent tempering fits into a broader transformation: the shift toward Industry 4.0 with intelligence and connectivity being built into chocolate production lines.

Key technologies include:

- IoT-enabled machinery that provides real-time feedback on temperature, viscosity, and flow;

- Predictive maintenance algorithms that prevent breakdowns and extend equipment life;

- Cloud-based AI-powered maintenance systems such as those provided by Rockwell Automation for remote monitoring and control.

Together, these systems offer manufacturers not just consistency and speed, but adaptability—a crucial asset in a world of customised products and fluctuating supply chains.

3D printing

Few technologies illustrate chocolate's creative potential like 3D printing. This fast-growing field allows for complex shapes, intricate textures, and even custom designs made to order.

Applications include:

- High-end personalised confectionery;

- Rapid prototyping of new mould designs and product formats;

- Small-batch or on-demand production, reducing waste and excess inventory.

3D chocolate printers require careful coordination of temperature control, nozzle mechanics, motion systems, and extrusion algorithms – each offering a potential area for innovation and IP.

Sustainability

Today’s chocolate producers must do more than make high quality chocolate – they must do so responsibly. Sustainability is now a top priority for chocolate brands, consumers, and machinery manufacturers alike.

Forward-thinking engineering teams are developing equipment that is:

- Energy-efficient, using smarter heating systems and improved insulation;

- Modular and upgradable, reducing the need for full system replacements;

- Water-conscious, with closed-loop cooling and cleaning systems;

- Waste-reducing, using inline sensors to minimise scrap and product loss.

As sustainability becomes not just a social goal but a market requirement, machinery that supports eco-friendly operations offers a compelling competitive edge.

From innovation to protection: IP as a strategic asset

With all this progress, one question looms large: Is your innovation protected?

If your company is developing machinery for chocolate production lines, you could be sitting on valuable IP. And if that IP isn’t secured, it’s exposed to imitation. A comprehensive IP strategy doesn’t just safeguard innovation – it supports business growth, licensing opportunities, and long-term value creation.

Conclusion: smarter machinery, smarter protection

From autonomous harvesters in the tropics to robotic arms on the production line, chocolate manufacturing is being reshaped by innovation. Whether you're building precision tempering systems, intelligent enrobers, or 3D printers for chocolate, your work is defining the future of this global industry.

But to maximise the value of innovation, protection must evolve alongside it. To find out more about protecting your innovations get in touch with our team.

Read our other blog to learn more about the various technologies being used by innovators to replicate or replace traditional cocoa.

Rachel is a member of our engineering and chemistry & materials patent teams and has experience working in a number of industry sectors including transport, Medtech, food & beverage, industrial chemistry, mechanical & structural engineering and Cleantech. Rachel deals mainly with original drafting, prosecution, opposition and opinion work. Her clients include British universities, UK-based SMEs, domestic and overseas corporations.

Email: rachel.oxley@mewburn.com

Sign up to our newsletter: Forward - news, insights and features

Our people

Our IP specialists work at all stage of the IP life cycle and provide strategic advice about patent, trade mark and registered designs, as well as any IP-related disputes and legal and commercial requirements.

Our peopleContact Us

We have an easily-accessible office in central London, as well as a number of regional offices throughout the UK and an office in Munich, Germany. We’d love to hear from you, so please get in touch.

Get in touch/RACHEL%20OXLEY2-1-1.png?width=100&height=100&name=RACHEL%20OXLEY2-1-1.png)