We’ve previously discussed how energy can be captured directly from the movement of the waves on the ocean or from the winds that create those waves. One other way to capture energy from the ocean is via ocean thermal energy conversion (OTEC).

What is ocean thermal energy conversion?

When talking about ocean energy, it is often noted that the ocean covers 70% of the earth’s surface. That, of course, means that 70% of sunlight that hits the earth hits the ocean.

Sunlight heats the surface of the ocean, producing a difference in temperature between the surface of the ocean (hot) and its depths (cool). Differences in temperature are useful in the conversion of energy because of the fact that they can be used to drive fluid movement which can in turn be used to rotate a turbine to generate electricity. There are two main types of OTEC system which exploit this concept, in slightly different ways.

Closed cycle systems

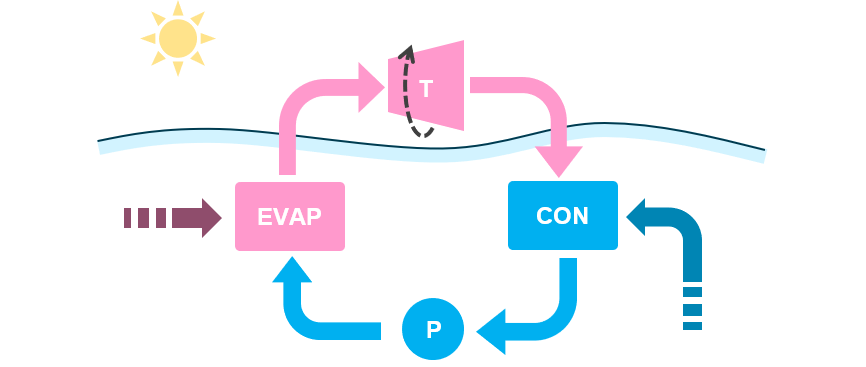

A closed cycle system uses a working fluid, which is typically ammonia (we’ve previously discussed the benefits of ammonia as a working fluid in air conditioning systems). The working fluid is pumped through a cycle (shown below) by a pump (P). The working fluid, in liquid form, is heated at an evaporator (EVAP), which vaporises the liquid (i.e. converts the liquid to a vapour). This expands the working fluid, and increases its pressure, causing it to rotate a turbine T. The working fluid is then cooled at a condenser which, as the name suggests, condenses the fluid back into a liquid. This closed cycle is repeated to provide continuous rotation of the turbine, which can be used to generate electricity.

How is the working fluid heated and cooled in the evaporator and condenser?

This is where ocean temperature gradients come into play. The evaporator (where the working fluid is vaporised) is in fact a heat exchanger that exchanges heat from (hot) surface ocean water to the working fluid to increase the temperature of the working fluid. The condenser is also a heat exchanger, but in this case, heat is exchanged from the working fluid to (cold) ocean water that is pumped from the depths of the ocean (the cold ocean water cools the working fluid). The cold water must be pumped from the depths of the ocean, which requires electricity. However, where there is a sufficient difference in temperature between the surface ocean water and the cold deep ocean water, the electricity produced by the turbine outweighs that needed to pump the ocean water.

Open cycle systems

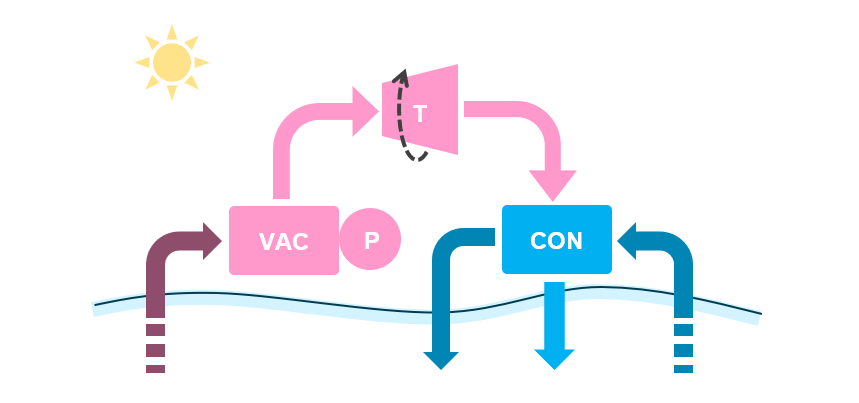

An open-cycle system works in a similar manner to a closed cycle system, except that it forgoes the working fluid. Instead, it is the (hot) surface ocean water itself that drives the turbine to generate electricity. The surface ocean water first enters a vacuum chamber (VAC) in which the pressure of the ocean water is lowered by a pump (P). This causes the ocean water to flash evaporate into steam, because lowering the pressure of a fluid has the effect of lowering the temperature at which it fluid boils. The steam drives the turbine, which generates electricity. Finally, the steam is cooled and condensed in a condenser, using (cold) deep ocean water.

Unlike the closed cycle system, in the open cycle system the condensed water does not then cycle back through the evaporator. Instead, the water can simply be dumped back into the ocean or, usefully, it can provide a source of drinking water. This is because, when the surface water is flashed into steam, all the salt in the seawater drops out of the steam and is not then carried through the system – the water that comes out of the condenser is fresh water. This can be a very desirable characteristic of open-cycle OTEC systems, especially in locations where there is otherwise limited availability of fresh water.

What are the challenges?

OTEC systems sound great – they provide a continuous source of renewable energy and in some cases even have the added benefit of supplying fresh drinking water. So why are these systems not already installed all along the earth’s coastlines?

One answer is that they are simply not viable at all locations on earth. OTEC systems, as mentioned above, are heavily reliant on a temperature gradient between the surface of the ocean and its depths. The smaller the difference in temperature, the less energy an OTEC system will produce. To be viable, OTEC systems require a temperature difference (between the surface water and the cold water) of about 20°C. That sort of temperature difference is only present, however, in hotter (tropical and subtropical) regions of the earth where the ocean is sufficiently deep. OTEC is probably not, for example, going to be viable off the coast of the UK.

But even then, assuming you find a suitable location or your OTEC system, there are significant engineering challenges in implementing such a system. The cold water, for example, must be pumped from depths of 1 kilometre or more under the surface of the ocean. Not only does this introduce technical difficulties, but it also means the upfront capital cost of such a system can be extremely high.

This means that OTEC systems currently in operation today are non-commercial systems installed for testing purposes. Many of these systems are installed around tropical islands (a tough life for OTEC engineers) where large ocean temperature gradients exist, but also where a source of continuous power is highly valuable and where fresh drinking water can be sparse.

What’s next for OTEC?

OTEC systems have been around for a long time – the first system was installed by entrepreneur George Claude in the 1930s, although the concept was first proposed much earlier than that. Since then, interest in OTEC seems to have come in waves, with small periods of progress interspersed by larger periods of stagnation. We seem to be in a period of progression right now, likely driven by the growing recognition that the world needs to move to more sustainable power generation and needs to do so quickly. As more money is poured into finding a solution, it is hoped that some of that finds its way into OTEC where the biggest hurdle seems to be those initial capital costs needed to install a system. Once a commercial system is built, the expectation is that it will drive more investment into the field which will accelerate the use of OTEC worldwide.

Of course, that is dependent on such a commercial system operating successfully, both technically and economically. In theory at least, that seems like a reasonable outcome, but as things stand it is by no means a certainty. As patent attorneys, we are always excited to see interesting technologies become commercial realities – especially those that have potential to improve the natural environment in which we live. On that basis at least, we hope the OTEC industry finds a winner at some point in the not-so-distant future.

To learn more about marine and ocean engineering or talk to one of our specialists, visit our Spotlight Page.

Ben is a Partner and Patent Attorney at Mewburn Ellis. Ben is experienced in patent drafting, prosecution and Freedom to Operate within the mechanical engineering, medical device and consumer products sectors. He also deals with filing and infringement issues relating to registered and unregistered designs.

Email: ben.boyd@mewburn.com

Sign up to our newsletter: Forward - news, insights and features

Our people

Our IP specialists work at all stage of the IP life cycle and provide strategic advice about patent, trade mark and registered designs, as well as any IP-related disputes and legal and commercial requirements.

Our peopleContact Us

We have an easily-accessible office in central London, as well as a number of regional offices throughout the UK and an office in Munich, Germany. We’d love to hear from you, so please get in touch.

Get in touch/BEN%20BOYD-author.png?width=100&height=100&name=BEN%20BOYD-author.png)