November is National Diabetes Awareness month and, in this blog, we are discussing the latest developments for treating and managing diabetes. We wrote earlier this month about developments in treatments to cure type 1 diabetes. But what about medical devices that can be used for diabetes management?

People with diabetes have high blood sugar levels due to the body not having a sufficient supply of insulin. Insulin is a hormone made in the pancreas that helps the body process glucose for energy. In type 1 diabetes the body can’t make the hormone insulin at all and in type 2 the body is not making enough insulin or the insulin it makes is not working properly due to insulin resistance. Left untreated, high blood sugar levels can cause damage to the body so it is important to keep blood sugar levels within a safe range. For type 1 diabetics and some type 2 this involves injecting insulin manually.

Smart Insulin Pens

Insulin Pens were first developed in the 1980s to provide a more simple, accurate and convenient delivery of insulin over syringes1. The first insulin pen, NovoPen, was released by Novo Nordisk in 1985. The increased dose accuracy of these pens supports blood glucose stability.

The latest development of this technology is smart insulin pens. These devices have a memory storage and automatically record the data on insulin doses. This therefore eliminates the requirement of patients to manually keep track and reduces the likelihood of errors. They can also display to users the time since the last dose and if a dose has been missed.

The data can be transferred from the pen to a device such as a smartphone or a PC using Near Field Communication (NFC) technology. The data can be viewed by the patient and sent to a healthcare provider to provide more accurate dosing history for appointments and consultations.

This technology prevents incomplete or inconsistent dosing data which improves the time patients spend with optimal glucose levels2. They can also reduce a patient’s anxiety about missing a dose or remembering when they last injected.

The two latest pens from Novo Nordisk have recently been made available on NHS prescription – the NovoPen 6 and the NovoPen Echo Plus.

Image from https://www.novonordisk.com/our-products/smart-pens/novopen-6.html

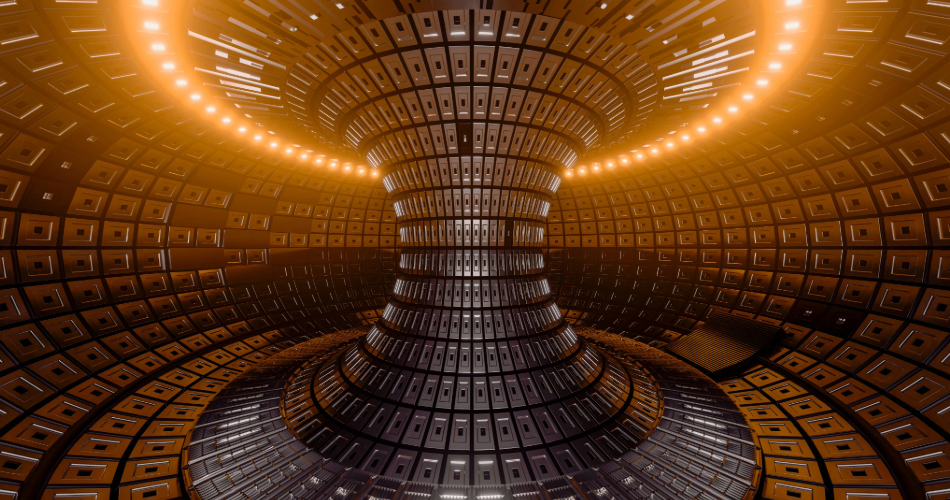

Hybrid Closed Loop Systems

Devices that completely automate insulin delivery and remove the need for manual injections have been in development since the early 1960s. These devices are designed to mimic the physiological insulin release from pancreatic beta cells, which means they are often referred to as an 'artificial pancreas'. The initial bulky technologies have been developed into the miniature, wearable devices available today.

A modern hybrid closed loop system is made up of three components:

- a continuous glucose monitor (CGM) consisting of a small sensor that sits under the skin and sends blood sugar readings to an external device,

- a computer programme that uses an algorithm to process the measured blood sugar data (and the manually input carbohydrate data at mealtimes) and calculate how much insulin is needed, and

- an insulin pump which releases the calculated amount of insulin into the body when required.

These devices have been shown to keep blood sugar levels more stable3 which reduces hypos and risks of diabetes complications. They also remove the requirement for patients to do regular finger-prick testing or self-inject insulin.

There are currently four systems regulated in the UK by the Medicines and Healthcare Products Regulatory Board (MHRA):

- Omnipod 5 tubeless pump with the Dexcom G6 CGM.

- CamAPS FX app with the Dexcom G6 CGM or Dana Diabecare RS and DANA-i insulin pumps.

- Medtronic 780g insulin pump with the Guardian 4 Sensor CGM.

- Tandem Tslim Control IQ insulin pump with the Dexcom G6 CGM.

The National Institute for Health and Care Excellence (NICE) have recently completed an assessment of hybrid closed loop systems and announced a 5-year roll-out plan of hybrid closed loop systems in England and Wales for type 1 diabetes patients through the NHS.

Smart Wound Sensors

High blood sugar levels in diabetic patients can cause diabetic polyneuropathy (DPN) when the blood vessels that supply the nerves in the body become damaged. The restricted blood flow damages the nerve fibres which cannot repair themselves. The longest nerves extending from the spine to the feet are typically affected the most.

DPN can make a patient more at risk of injuries to the feet such as foot ulcers, which take longer to heal due to restricted blood flow reducing the infection-fighting cells reaching the wound. Foot ulcers are more susceptible to infections and 20% of moderate and severe diabetic foot infections lead to amputations4.

Currently, wounds are regularly redressed by healthcare professionals so they can visually assess the healing. However, this can encourage infection of the wound and disrupt the progress of the healing. It also requires a significant amount of time and money to carry out the inspection with diabetic wound management currently costing the NHS between £837 and £962 million a year5.

A new smart wound dressing is being developed by researchers at the University of Nottingham which incorporates optical fibre sensors. These sensors can monitor the temperature, humidity and gases associated with healing and infection. Monitoring these parameters can allow the wound to be continuously assessed for infection or any issues with healing remotely, without requiring a visual inspection.

Implementing these smart wound dressings would save the NHS the money currently spent on appointments for manual inspection of wounds and allow quicker and more accurate interventions when a wound is infected, potentially reducing the number of amputations required.

Image from University of Nottingham

Future advances

There are many exciting, new developments in medical devices which can improve the management and treatment of diabetes and diabetes-related conditions. Hopefully, more innovation will lead to the reduced impact of diabetes on patients’ lives. This is increasingly important as the number of people living with diabetes in the UK increases every year – numbers reached 5 million for the first time this year. Our Medtech team are keeping a close eye on how technology is advancing in this area.

References

- Kesavadev J, Saboo B, Krishna MB, Krishnan G. Evolution of Insulin Delivery Devices: From Syringes, Pens, and Pumps to DIY Artificial Pancreas. Diabetes Ther. 2020 Jun;11(6):1251-1269. doi: 10.1007/s13300-020-00831-z. Epub 2020 May 14. PMID: 32410184; PMCID: PMC7261311.

- Adolfsson P, Hartvig NV, Kaas A, Møller JB, Hellman J. Increased Time in Range and Fewer Missed Bolus Injections After Introduction of a Smart Connected Insulin Pen. Diabetes Technol Ther. 2020 Oct;22(10):709-718. doi: 10.1089/dia.2019.0411. Epub 2020 Mar 11. PMID: 32003590; PMCID: PMC7591375.

- Templer S. Closed-Loop Insulin Delivery Systems: Past, Present, and Future Directions. Front Endocrinol (Lausanne). 2022 Jun 6;13:919942. doi: 10.3389/fendo.2022.919942. PMID: 35733769; PMCID: PMC9207329.

- Senneville É, Lipsky BA, Abbas ZG, Aragón-Sánchez J, Diggle M, Embil JM, Kono S, Lavery LA, Malone M, van Asten SA, Urbančič-Rovan V, Peters EJG. Diagnosis of infection in the foot in diabetes: a systematic review. Diabetes Metab Res Rev. 2020 Mar; 36 Suppl 1:e3281. doi: 10.1002/dmrr.3281. PMID: 32176440.

- Kerr M, Barron E, Chadwick P, Evans T, Kong WM, Rayman G, Sutton-Smith M, Todd G, Young B, Jeffcoate WJ. The cost of diabetic foot ulcers and amputations to the National Health Service in England. Diabet Med. 2019 Aug;36(8):995-1002. doi: 10.1111/dme.13973. Epub 2019 Jun 5. PMID: 31004370.

Emily is a trainee patent attorney working as part of the Engineering practice group. She has a MSci and PhD in Physics from the University of Birmingham. Before becoming a patent attorney, Emily worked as a software engineer at a CAD/CAM software company and an e-commerce company utilising AI-powered technologies to improve operations.

Email: emily.lloyd@mewburn.com

Sign up to our newsletter: Forward - news, insights and features

Our people

Our IP specialists work at all stage of the IP life cycle and provide strategic advice about patent, trade mark and registered designs, as well as any IP-related disputes and legal and commercial requirements.

Our peopleContact Us

We have an easily-accessible office in central London, as well as a number of regional offices throughout the UK and an office in Munich, Germany. We’d love to hear from you, so please get in touch.

Get in touch